Heavy Load Rail Guided Vehicle RGV

description

RGVs are automated vehicles that move along a predetermined path on rails to transport raw materials, finished goods, or tools within a manufacturing plant. They are highly versatile and can transport loads ranging from a few hundred kilograms to several tonnes.

RGVs operate autonomously, navigate safely in hazardous environments, carry varying loads, and require minimal maintenance. All of these extensive benefits lead to significantly lower production costs and increased productivity.

Advantage

• AUTONOMOUS NAVIGATION

One of the primary benefits of RGVs is their ability to operate autonomously. Once programmed, RGVs navigate their way around the factory without human interference, ensuring round-the-clock material handling operations. The automated system eliminates human errors and reduces the need for manual labor, leading to cost savings and increased efficiency.

• ADVANCED SENSOR TECHNOLOGY

RGVs are equipped with advanced sensor technology that helps them navigate their path, detect obstacles and respond to changing situations. The high level of automation provided by RGVs ensures that they can operate in hazardous environments unsuitable for human operators.

• ENHANCE PRODUCTIVITY

Manufacturing plants have seen a significant increase in capacity utilization, reducing the time taken to complete production cycles with the implementation of RGVs. They offer a reliable and efficient way of material handling, leading to improved production process outcomes.

• SAFETY

Embracing RGV technology enables manufacturing plants to reduce manual labor expenditure and create a safer, more efficient, and streamlined working environment. The advanced sensor and automation technology ensures that the manufacturing process is optimized, with minimal human intervention.

Application

The need for mechanical production keeps upgrading and changing the handling tools. RGV for machinery manufacturing, automobile manufacturing, military industry, shipbuilding and other industries, need to transport the workpiece, materials and goods can be easily transported.

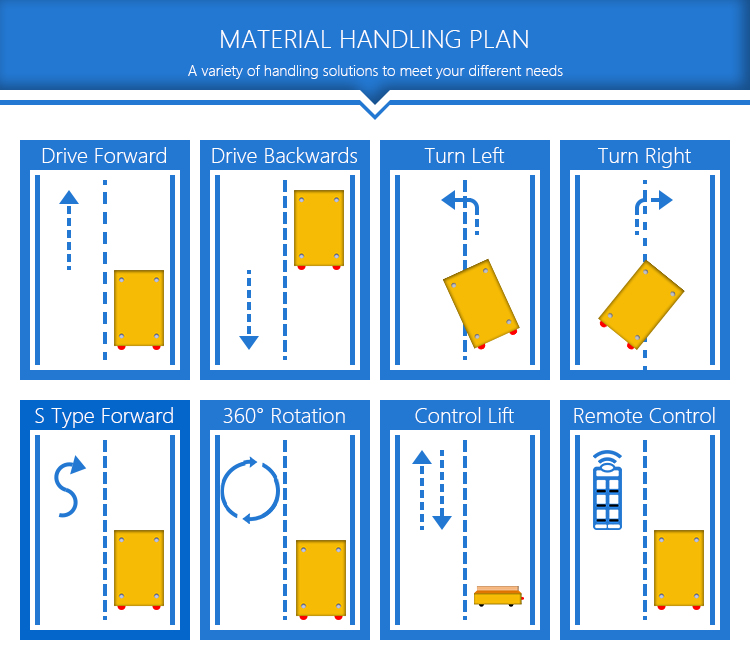

Handling methods