Battery 75 Ton Assembly Line Trackless Transfer Cart

description

The maximum load-bearing capacity of this battery 75 ton assembly line trackless transfer cart is up to 75 tons, which can meet the needs of most industrial production. The maintenance-free battery design greatly reduces the frequency and cost of maintenance work, saving you valuable time and energy. Moreover, the dual-motor drive design can not only provide greater driving force, but also ensure the starting stability of the trackless transfer cart, which is especially suitable for use in production lines with frequent starts and stops. This design can greatly improve production efficiency, reduce production line downtime, and extend the service life of the trackless transfer cart. The polyurethane solid rubber-coated wheels can effectively reduce noise and ground wear, extend service life, and greatly reduce maintenance costs. Moreover, wheels made of polyurethane are corrosion-resistant and can maintain stable performance even when used in harsh environments.

Application

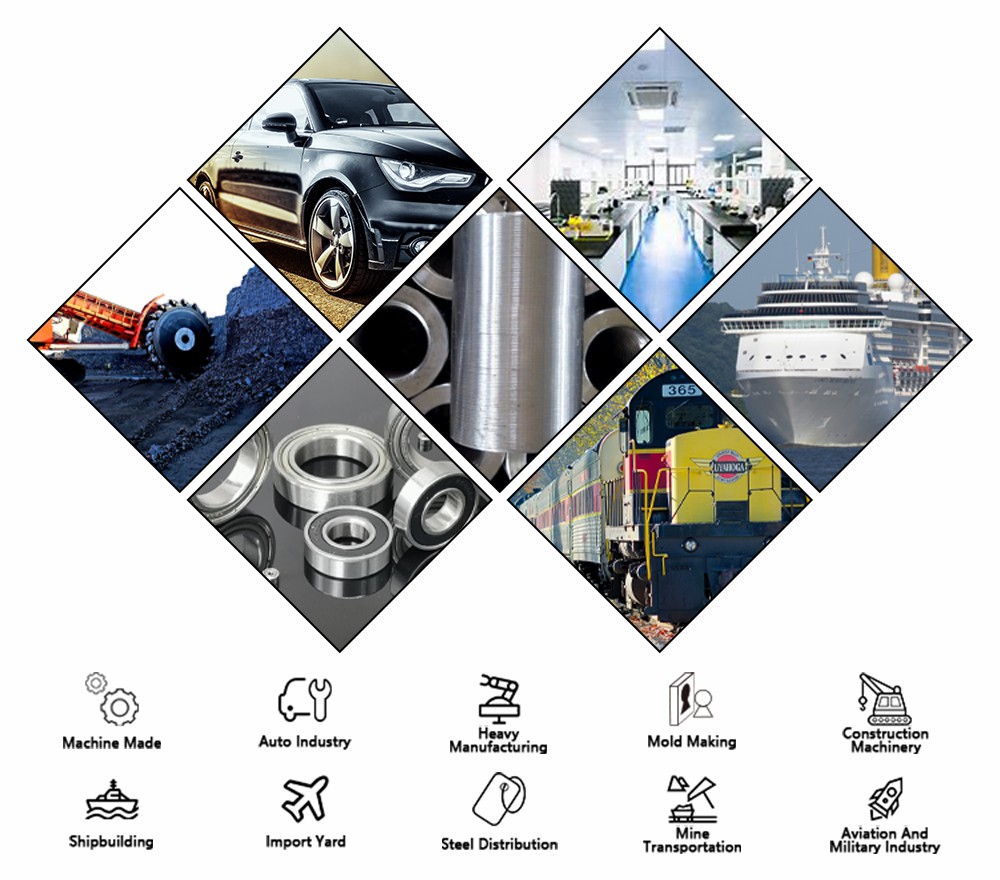

The battery 75 ton assembly line trackless transfer carts are widely used in various industrial assembly lines, mainly in the following aspects:

1. Metal processing: In metal processing production lines, trackless transfer carts can be used to transport metal materials or semi-finished products, improving production efficiency and reducing worker labor intensity.

2. Paper industry: On the production line of a paper mill, trackless transfer carts can be used to transport paper or pulp to achieve rapid movement and distribution of materials.

3. Automobile manufacturing: In automobile manufacturing factories, trackless transfer carts can be used to transport automobile parts, such as engines, chassis, etc., to increase automobile manufacturing production capacity.

4. Ship manufacturing: In the ship manufacturing industry, trackless transfer carts can be used to transport large hull components to improve the efficiency of ship manufacturing.

Advantage

The battery 75 ton assembly line trackless transfer carts have a series of advantages compared to traditional rail transport equipment, which are mainly reflected in the following aspects:

1. No need to lay tracks: The trackless transfer cart adopts a trackless design, which eliminates the need to lay a complex track system, simplifying the installation process and reducing costs.

2. High flexibility: The trackless transfer cart can travel freely on the assembly line, and can adjust its path according to actual needs to adapt to different working environments and work needs.

3. Easy maintenance: It adopts advanced technology, has good stability and reliability, is easy to maintain, and reduces maintenance costs.

4. Safe and reliable: The trackless transfer cart is equipped with various safety protection devices, which can accurately sense the surrounding environment and obstacles to ensure safety during the transport process.

Customized

More importantly, this battery 75 ton assembly line trackless transfer cart also has the characteristics of flexible customization and can be personalized according to your needs. Whether it is an increase in load capacity or an adjustment in size, we can meet your requirements. Moreover, during the design and customization process, our professional team will provide you with the best solution based on your working environment and usage requirements to ensure that the trackless transfer cart can perfectly adapt to your production line.

In conclusion, as an important part of modern industrial production, assembly lines have increasingly higher requirements for handling equipment. As an efficient and flexible handling tool, the battery 75 ton assembly line trackless transfer cart has unique advantages in improving production efficiency and reducing costs. It is believed that with the advancement of technology, electric trackless transfer carts will be used in more fields and bring more convenience and benefits to people.