Hot Selling Workshop Use 10T Heavy Duty Electric Transfer Agv

Persisting in “High top quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients’ large comments for Hot Selling Workshop Use 10T Heavy Duty Electric Transfer Agv, We, with great passion and faithfulness, are ready to give you with best companies and striding ahead with you to create a vibrant foreseeable future.

Persisting in “High top quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients’ large comments for 10t heavy duty agv, China made agv, electric transfer agv, workshop use transfer agv, Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Advantage

• HIGH FLEXIBILITY

Equipped with innovative navigation technologies and sensors, this heavy duty automatic AGV is capable of operating autonomously and seamlessly maneuvering through dynamic work environments with ease. Its advanced features allow it to navigate through complex terrains, avoiding obstacles in real-time, and adapt to changes in production schedules.

• AUTOMATIC CHARGING

One major feature of the heavy duty automatic AGV is its automatic charging system. This allows the vehicle to recharge autonomously, minimizing disruptions in the manufacturing process and saving precious time. The system also ensures that the vehicle remains operational throughout the day, without downtime due to battery charges.

• LONG-RANGE CONTROL

The heavy duty automatic AGV is easy to integrate into existing systems, with the ability to connect to warehouse management systems to improve workflow efficiency. Supervisors can monitor the vehicle’s movements, performance, and operational status from remote locations and proactively address any issues that may arise.

Application

Technical Parameter

| Capacity(T) | 2 | 5 | 10 | 20 | 30 | 50 | |

| Table Size | Length(MM) | 2000 | 2500 | 3000 | 3500 | 4000 | 5500 |

| Width(MM) | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | |

| Height(MM) | 450 | 550 | 600 | 800 | 1000 | 1300 | |

| Navigation Type | Magnetic/Laser/Natural/QR Code | ||||||

| Stop Accuracy | ±10 | ||||||

| Wheel Dia.(MM) | 200 | 280 | 350 | 410 | 500 | 550 | |

| Voltage(V) | 48 | 48 | 48 | 72 | 72 | 72 | |

| Power | Lithium Battey | ||||||

| Charging Type | ManualCharging / Automatic Charging | ||||||

| Charging Time | Fast Charging Support | ||||||

| Climbing | 2° | ||||||

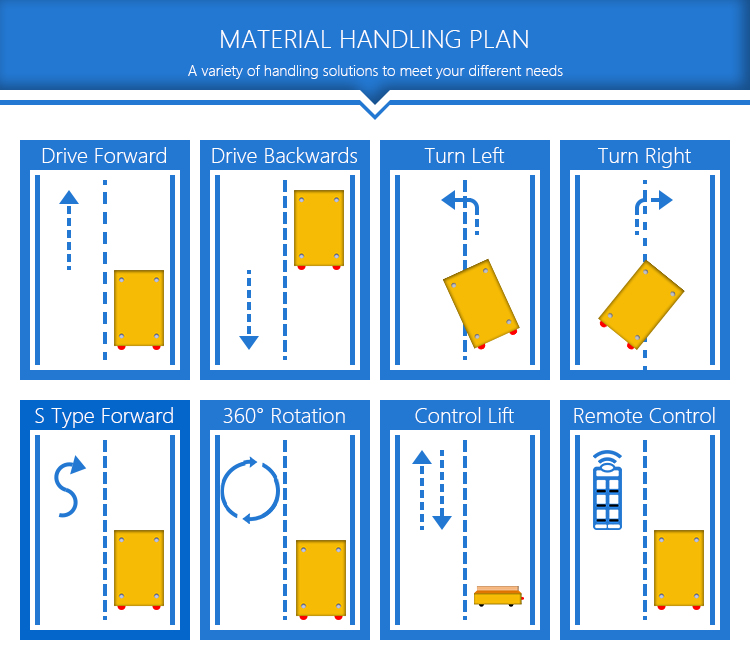

| Running | Forward/Backward/Horizontal Movement/Rotating/Turning | ||||||

| Safer Device | Alarm System/Multiple Snti-Collision Detection/Safety Touch Edge/Emergency Stop/Safety Warning Device/Sensor Stop | ||||||

| Communication Method | WIFI/4G/5G/Bluetooth Support | ||||||

| Electrostatic Discharge | Yes | ||||||

| Remark: All AGVs can be customized, free design drawings. | |||||||

Handling methods

Handling methods

Electric transfer AGV technology has been gaining traction in the industrial sector as they provide efficient and reliable material handling solutions. One such popular system is the 10T heavy-duty electric transfer AGV, which is in high demand due to the numerous benefits it offers.

This electric AGV is capable of carrying loads up to 10T, making it ideal for heavy-duty applications. It is designed with a robust and durable frame, ensuring it can endure even the toughest working conditions. Furthermore, it does not emit any harmful gases, making it an environment-friendly option.

The electric AGV is equipped with advanced sensors and navigation technology, ensuring that it moves accurately and safely. The system also minimizes the risk of human error, reducing the chances of accidents in the workplace. This factor is essential, particularly in high-risk industries that deal with hazardous materials.

The electric AGV system can be easily integrated into existing manufacturing processes, making it an efficient and cost-effective solution. It can increase efficiency and productivity by reducing downtimes and eliminating any bottlenecks in material handling. This ultimately results in increased profitability and reduced operational costs.

In conclusion, the 10T heavy duty electric transfer AGV is a game-changer in the industrial sector. Its numerous benefits make it a hot-selling workshop item that is in high demand. It provides an efficient, reliable, and eco-friendly material handling solution that can revolutionize the way industries operate.