5T Welding Use Roller Electric Rail Transfer Cart

First of all, the 5t welding use roller electric rail transfer cart is powered by batteries, abandoning traditional fuel drive, making transportation more portable and environmentally friendly, and also avoiding the impact of sudden power outages on work. The track laid by it allows the transfer cart to travel according to the prescribed route and work at fixed points, which greatly improves work efficiency. Special mention should be the roller device of the 5t welding use roller electric rail transfer cart. This kind of transfer cart uses an advanced rubber roller device, which can effectively increase the friction of the welding material and reduce noise. At the same time, the roller operation allows the welding material to rotate 360 degrees. In addition, the roller device can also adjust the speed according to the actual situation to adapt to the welding needs of different heavy objects, greatly improving the flexibility and efficiency of welding.

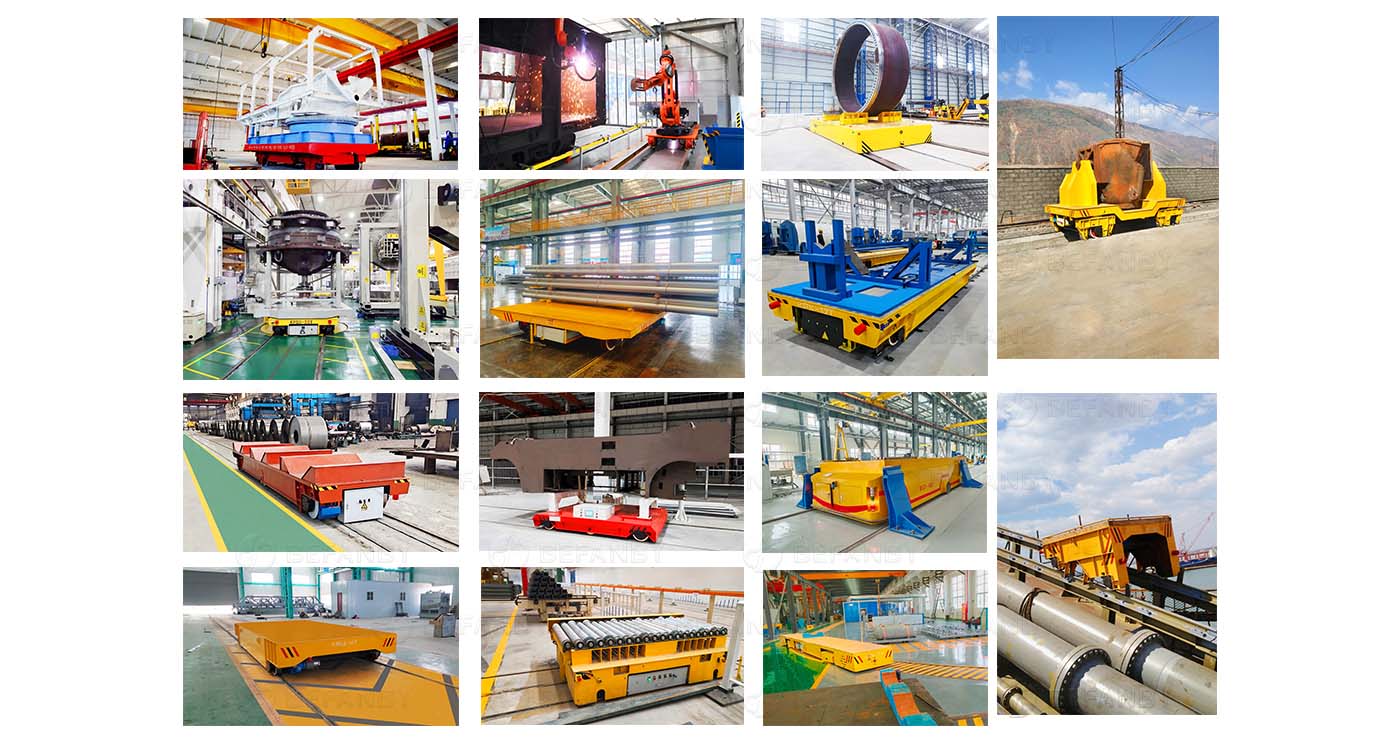

Secondly, in practical applications, the use of the 5t welding use roller electric rail transfer cart has achieved good results and responses. Many companies have adopted this smart handling tool and achieved very significant benefits. Whether in automobile manufacturing, machine tool processing or other heavy industrial production fields, it can become a powerful assistant in industrial production. With its help, workers no longer need to invest too much manpower and can focus more on other aspects of their work, truly freeing their hands.

Next, let’s take a look at the advantages of using the 5t welding use roller electric rail transfer cart. Compared with traditional handling equipment, this kind of transfer cart is not only small in size, but also adopts a compact design, which can flexibly operate in a small space and accurately deliver heavy objects to the destination. Whether in warehouses, factories or other small spaces, it can easily shuttle, improve handling efficiency, and save manpower and time. At the same time, the compact design also facilitates welding personnel to easily operate the welding tools, effectively avoiding the inconvenience caused by excessive size.

In addition to the above-mentioned advantages, the 5t welding use roller electric rail transfer cart also has many other surprising features. It is equipped with an advanced intelligent control system that can automatically avoid obstacles without manual intervention, improving work safety and stability. At the same time, it also supports remote control operation, so operators can grasp the handling progress in real time and manage the production process more efficiently.

At the same time, our transfer carts also provide customization and after-sales services. Since different industries have different needs for material handling vehicles, our technical team can customize a perfect solution based on your specific factory conditions and needs, making your work more convenient. It is our consistent principle to provide users with after-sales protection. Only when our customers feel at ease can we feel at ease.

To sum up, the 5t welding use roller electric rail transfer cart has become an indispensable part of industrial production due to its roller device and compact size. Its advanced technology and intelligent design have greatly improved handling efficiency and safety, bringing new changes to industrial production. In the future, it will continue to innovate and evolve to provide better handling solutions for all walks of life.